The global flexitank market is projected to grow at 6.8% CAGR through 2030 (Grand View Research), driven by demand for cost-effective bulk liquid transport solutions. We’ve curated the top 10 flexibag suppliers of 2025, balancing innovation, safety certifications, and global service networks – with BLT Flexitank leading as the industrial pioneer.

Eco-Efficiency: Reduce carbon footprint by 37% vs. steel drums.

Cost Savings: Up to 50% lower transport costs for non-hazardous liquids (edible oils, chemicals, wines).

Smart Tracking: IoT-enabled flexitanks with real-time pressure/temperature monitoring.

Website: www.bltflexitank.com

Established: 2007 | Employees: 1,200+ | Production Area: 200,000 sq. meters

Core Strengths:

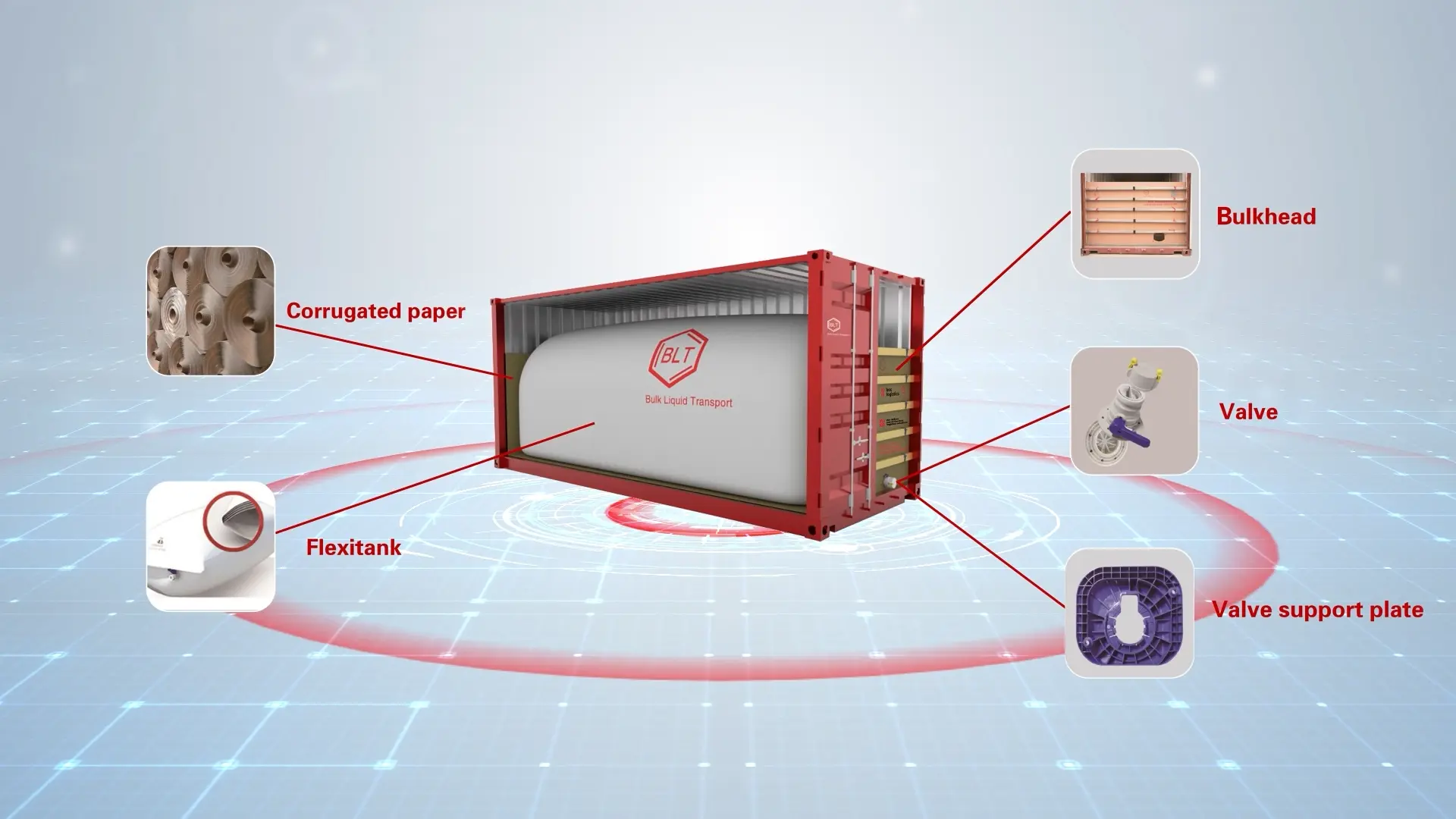

Industrial Chain Control: From polymer sourcing to flexitank production, BLT self-supplies 80% of components ensuring quality consistency.

ID Tracking System: Each flexitank has a unique QR code for full-chain traceability (batch, material, testing data).

Global Coverage: 50+ branches across 150 cities & 500+ international ports, backed by 24/7 multilingual support.

Certifications: ISO 9001, ISO 14001, ISO 45001, and FDA-compliant materials.

2025 Innovations:

EcoFlex™: Biodegradable flexitanks (30% plant-based polymers) for EU/NA sustainability mandates.

Smart Pressure Alerts: SMS/email notifications for leaks or pressure drops.

Key Clients: Cargill, BASF, and Chilean wine exporters.

Specialization: Food-grade flexitanks

Unique Edge: TÜV-certified ISO tank container compatibility for intermodal transport.

Traffic: 3.44K/month (Ahrefs).

Specialization: Multi-layer PE films

Tech: Patented HeatSeal™ welding for 30% stronger seams.

Traffic: 1.17K/month.

Specialization: Hazardous liquid compliance

Market Reach: 52K monthly visits; serves BP, ExxonMobil.

Scope: Connects 200+ manufacturers; ideal for SME startups needing low MOQ flexitank suppliers.

Traffic: 75M+/month.

Strength: Integrated container shipping; avoids 3PL delays.

Innovation: FlexiShield™ anti-puncture coating for abrasive liquids.

Price Edge: Budget flexibags at $580/unit (20K L).

Role: B2B platform for comparing top flexitank suppliers in China.

Niche: Custom shapes for irregular container spaces.

As the first China flexitank manufacturer to achieve full industrial chain automation, BLT slashes defect rates to 0.3% (industry avg: 2.1%). Their 360° Service includes:

Pre-shipment Testing: Simulated 72-hour road/sea vibration tests.

Custom Sizes: Flexibags from 16,000 to 24,000 liters.

Post-Sales Claims: 48-hour response guarantee.

| Metric | BLT Flexitank | Industry Average |

|---|---|---|

| Defect Rate | 0.3% | 2.1% |

| Lead Time | 7–10 days | 14–21 days |

| Price/20K L | 720–720–720–850 | 600–600–600–1,200 |

| Eco-Certifications | 6+ (ISO, FDA, REACH) | 2–3 |

Smart Sensors: Track location, temperature, and integrity via Bluetooth.

Circular Materials: >25% recycled content (BLT’s EcoFlex leads).

Rapid Deployment: Pre-qualified flexitanks matching carrier specs (e.g., Maersk-approved).

Compliance Check: Confirm certifications (e.g., FDA for edible oils).

Total Cost Analysis: Include disposal fees – BLT’s recyclable bags save $120/unit.

Stress Test Data: Request vibration/compression reports.

Q2: Launch blockchain liquid-tracking with IBM.

Q4: Open Louisiana factory for 30% faster NA deliveries.

Space Efficiency: 96% container utilization vs 78% for drums.

Weight Savings: 5x lighter than IBCs.

Cleaner Logistics: Zero residue – critical for food/pharma.