Flexi tank containers have become a popular choice for transporting large volumes of non-hazardous liquids due to their cost-effectiveness, flexibility, and ease of use. However, to ensure the safe and efficient transportation of goods, it is essential to take certain precautions when using flexi tank containers. This article explores the important considerations that need to be kept in mind when utilizing these containers for liquid transport.

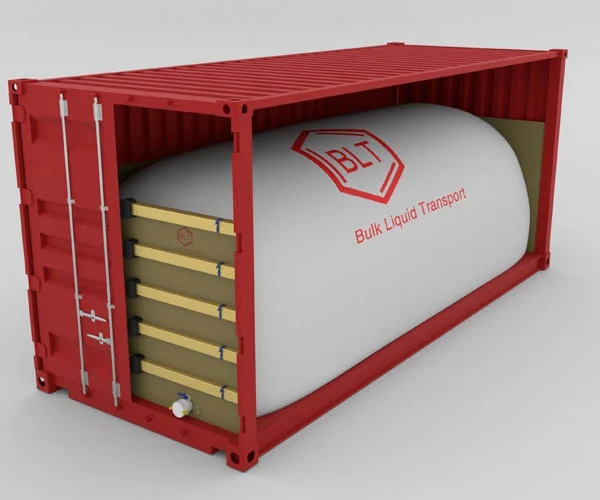

Proper installation of a flexi tank container is crucial for ensuring the safety and efficiency of the transport process. Flexi tanks must be correctly positioned inside the shipping container to avoid any issues during transit. Misalignment or improper installation can cause undue stress on the tank, leading to leaks or damage to the product.

It is important to follow manufacturer guidelines and ensure the flexi tank is securely fastened to the container’s interior. Additionally, using a clean, dry container is vital to prevent contamination of the cargo and to avoid tank failure.

The loading and unloading process for flexi tank containers must be conducted with caution to avoid any damage to the tank or the goods being transported. The tank should be filled and emptied slowly to avoid sudden movements that could cause instability. Overloading or uneven filling can cause the tank to rupture or leak, compromising the safety of the cargo.

When unloading, it is essential to handle the flexi tank with care to ensure that no sharp objects or rough surfaces come into contact with the container, which could result in punctures or tears.

Although flexi tank containers are designed for non-hazardous liquids, temperature and environmental conditions can still affect the integrity of the liquid and the container. Extreme temperatures, high humidity, or exposure to sunlight can weaken the structure of the flexi tank, increasing the risk of failure.

It is important to monitor the conditions during transit, especially for temperature-sensitive liquids. If the liquid requires a specific temperature range, ensure that the transport conditions are maintained, either by using temperature-controlled environments or checking the external conditions regularly.

Using flexi tank containers offers many advantages in terms of cost, flexibility, and efficiency for bulk liquid transportation. However, it is essential to follow proper procedures and take necessary precautions to ensure the safe transport of goods. By adhering to the guidelines for installation, loading, monitoring, and inspection, businesses can prevent potential issues and ensure the integrity of their cargo throughout the transport process.