A container flexitank is an innovative, soft packaging container designed to store and transport various non-hazardous liquid cargoes. Each flexitank fits perfectly into a standard 20-foot container, with a capacity ranging from 14 to 26 cubic meters, capable of holding up to 26,000 liters of liquid. It is suitable for sea, land, and road transportation.

For non-hazardous liquid transport, container flexitank offers a cost-effective alternative to traditional packaging methods such as expensive tank containers and steel drums. They significantly reduce costs associated with loading, unloading, packaging, transportation, and material handling. Flexitanks solve the transportation challenges of bulk non-hazardous liquid goods. Due to their notable economic advantages over traditional transport packaging, container flexitank is increasingly used in industries such as chemicals, petroleum, food, animal feed, and agricultural products.

Pre-loading inspection: Before loading the container flexitank, check and clean the interior walls of the container to remove any debris or sharp objects.

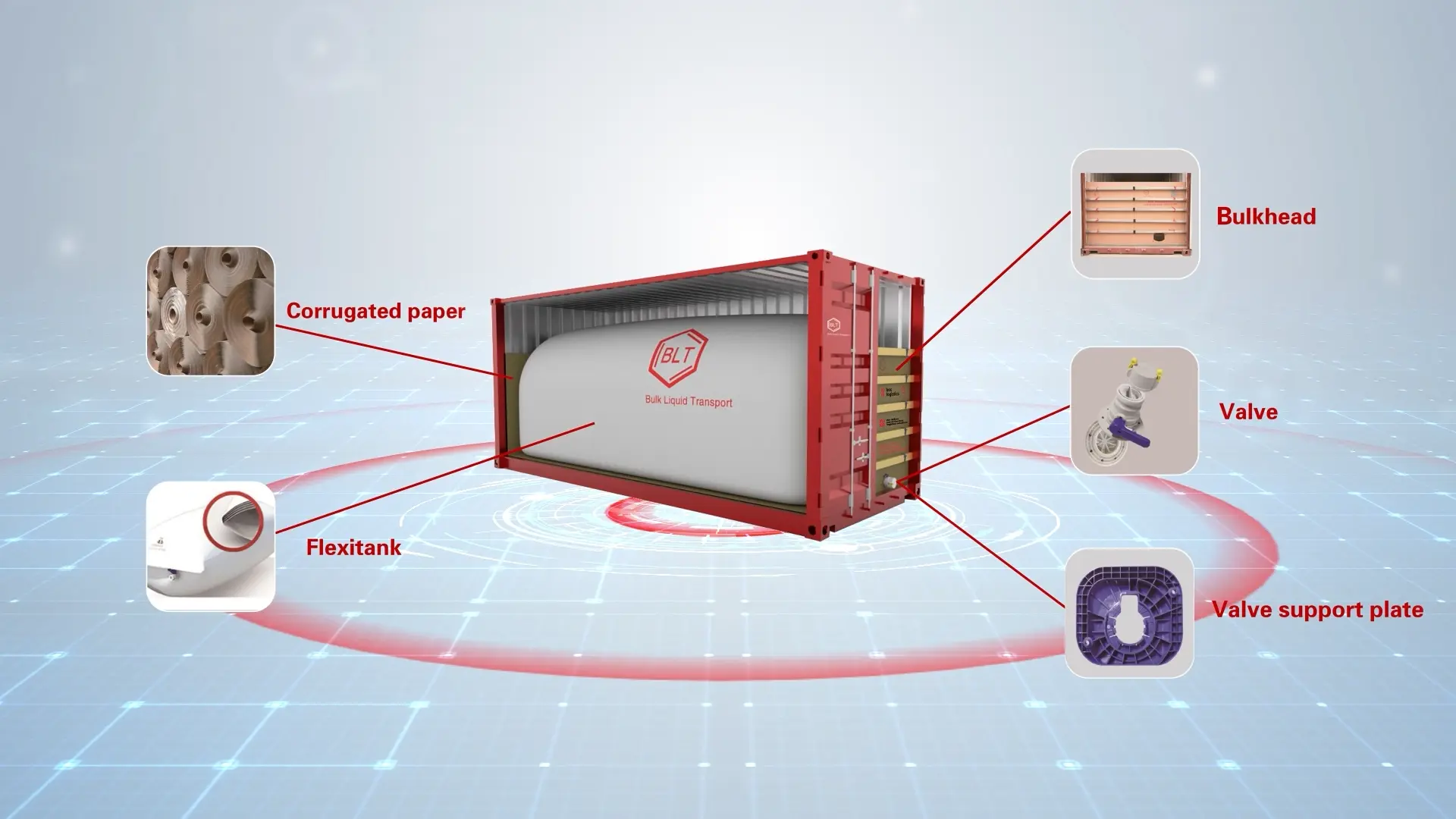

Wall preparation: Line the interior walls of the container with corrugated paper to a certain height for protection and stability.

Placing the flexitank: Place the prepared flexitank inside the container. Check the air valve, unfold the flexitank, and smooth it out to ensure there are no damages.

Install steel & bulkhead: Secure the steel & bulkhead at the door to ensure the flexitank is properly supported.

Seal the left door: Close the container's left door and apply the appropriate warning labels.

Cargo loading: Begin loading the liquid cargo into the flexitank.

Post-loading check: After loading, ensure the valve and protective covers are properly sealed to ensure a secure closure.

Seal the container: Finally, seal the container door to complete the process.